Polycarbonate & acrylonitrile butadiene styrene

PC/ABS is the material of choice when the application requires toughness, heat resistance, good formability, easy processing and high optical quality.

Abbreviation

PC/ABS

Molecular formula

C16H14O3

CAS no.

25037-45-0

General description

Polycarbonate/acrylonitrile butadiene styrene (PC/ABS) is a blend of PC and ABS. The combination combines the excellent impact strength and heat resistance of polycarbonate with the good processability of ABS. The optimum properties for specific applications are achieved by varying the ratio of polycarbonate and ABS and adding additives.

The synergistic effect of PC/ABS results in the high impact strength at low temperatures, the very good heat resistance and high dimensional stability as well as the easy colourability and printability of the material. PC/ABS blends are suitable for applications that require high load-bearing capacity as well as medium heat resistance in the range of +95 °C to +125 °C. The polymer blend shows good resistance when stressed in the low temperature range.

Definition

Polycarbonate (PC) is an amorphous engineering thermoplastic and is chemically a polyester. Its characteristic properties include high transparency, high heat resistance and outstanding impact strength. Polycarbonate is mainly used in the area of housings as well as moulded and optical parts.

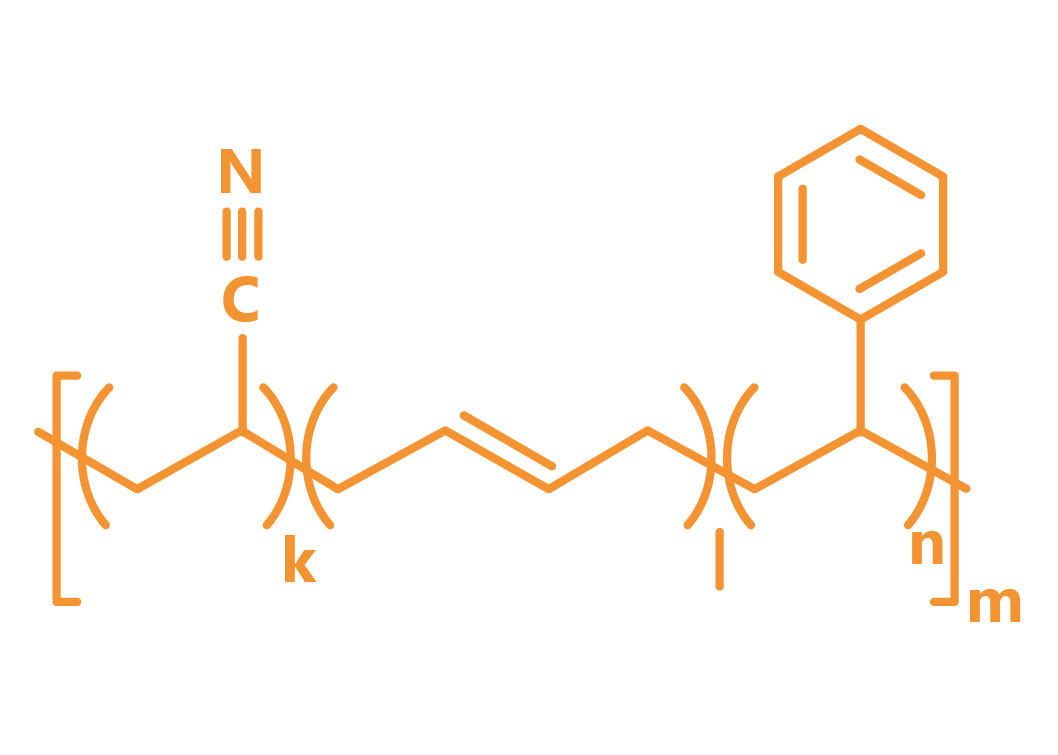

Acrylonitrile butadiene styrene (ABS) is an amorphous thermoplastic, belongs to the group of styrene polymers and is one of the bulk plastics. The three monomers styrene, butadiene and acrylonitrile are involved in the chemical structure of the material. The proportions of monomers involved in the polymerisation can be varied depending on the required properties.

ABS is easy to process and, due to its high polarity, easy to paint, which makes it ideal for use in aesthetic plastic products.

Production

Polycarbonate is produced by means of polycondensation from bisphenol A and diphenyl carbonate or from bisphenol A and phosgene using the melting process. The thermoplastic can be produced to be crystal clear and is stable over a wide temperature range. ABS plastics are two-phase systems that have particles of acrylonitrile butadiene rubber embedded in a matrix of styrene-acrylonitrile copolymer. Various processes are used for the production of ABS polymers.

If ABS is produced in an emulsion process for a homogeneous butadiene distribution, the material is characterised by a scratch-resistant and glossy surface. In addition, it is easily possible to paint or coat the material, for instance to obtain high-quality chrome-plated surfaces.

Properties

Amorphous polycarbonate is characterised by its good transparency, its light transmission, its temperature resistance as well as its breaking strength and dimensional stability. Further quality characteristics of the material are its medium to high strength and stiffness as well as a high creep modulus. Specific grades of the material are approved for food contact.

The material has a high polarity, which makes it ideal for coating, painting and printing. Plastic components made of the material, such as housings, are often chrome-plated, as galvanically applied metal layers adhere perfectly to them. PC/ABS blends combine the advantages of both materials. Due to the synergy effect, the material combination has high toughness, good creep resistance, dimensional stability, heat resistance and low moisture absorption even at low temperatures.

Chemical resistance

PC/ABS blends are chemically resistant to aliphatic hydrocarbons, weak mineral acids and weak organic acids, but not to alkalis, aromatic and halogenated hydrocarbons, ketones and esters. Polycarbonate is sensitive to hydrolysis because it is a polyester. Transparent, untreated PC yellows due to UV radiation during prolonged exposure to sunlight. Stabilisers or special films are used to ensure UV resistance.

Polycarbonate is resistant to many oils and greases as well as diluted acids and ethanol. However, the material is not resistant to aromatic and halogenated hydrocarbons, ketones and esters or alkalis.

Processing techniques

It is possible to shape PC/ABS blends using all available methods for thermoplastic moulding materials and thus process them on all industry-standard injection moulding machines. PC/ABS blends have very good thermal stability and balanced processing properties. The moulded parts that are produced have an impressive high-quality surface gloss. For best results, a high mould temperature and high injection speed are recommended. In principle, it is possible to use all common sprue types.

ABS plastic has the specific advantage that it can be processed extremely well in short cycles and has a flawless surface quality in the formed product. Surfaces can easily be finished by printing, chrome plating or painting.